TruView™ 10 is a scalable software platform that is available in all TruView™ X-ray systems. This common platform brings many advantages, allows to upgrade within the TruView™ family with minimal added training.

TruView™ 10 X-ray software is offered in two versions, depending on your needs and application. All TruView™ X-Ray systems ship with the TruView™ 10 Standard, while the TruView™ 10 Premium is optional.

TruView™ 10 Standard is packed with a full set of tools for data acquisition and annotation, including a complete database browser.

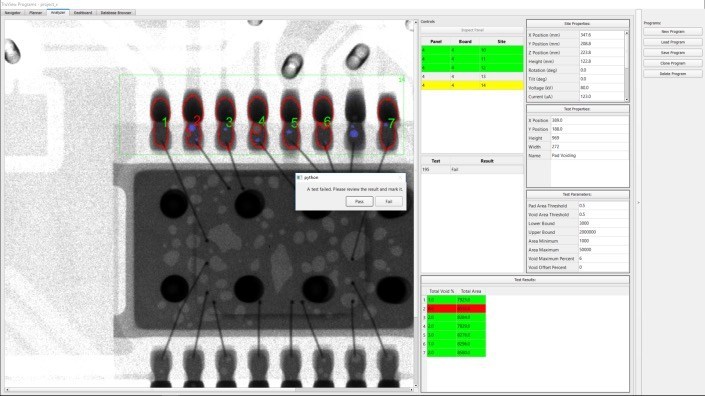

TruView™ 10 Premium turns Fussion X-ray system into a fully automated inspection machine. Customer selects the area he’d like to inspect, determinates tests to be performed and the reference image. System compares images with the pattern and generate pass/fail massages. Software keeps a complete statistics of testing boards and generate reports.

TruView™ 10 Premium turns Prime X-ray system into a semi- automated inspection machine. It works similar as above but will not give automatically pass/fail information.

TruView™ 10 Premium brings a set of powerful tools for Cube X-ray system. It acquires images and support its’ one by one analysis.

TruView™ Inspector is a powerful upgrade to your TruView™ Parts Counter AI. This upgrade allows to quickly and efficiently perform X-ray inspection of samples (like medical devices, PCB, castings) by comparing production units to a known-good sample as a to reference image. The TruView™ Inspector runs on our proprietary algorithms that perform image registration and comparison so the customer can spot check production without stopping the production line. Some of the great features of your TruView™ Inspector include:

- One button push to program the board

- Easy to use: fast to add to your manufacturing process

- Find SMT defects on your PCB: shorts, opens, voids, missing components

- Detect counterfeit components

- Identify wrong component orientation