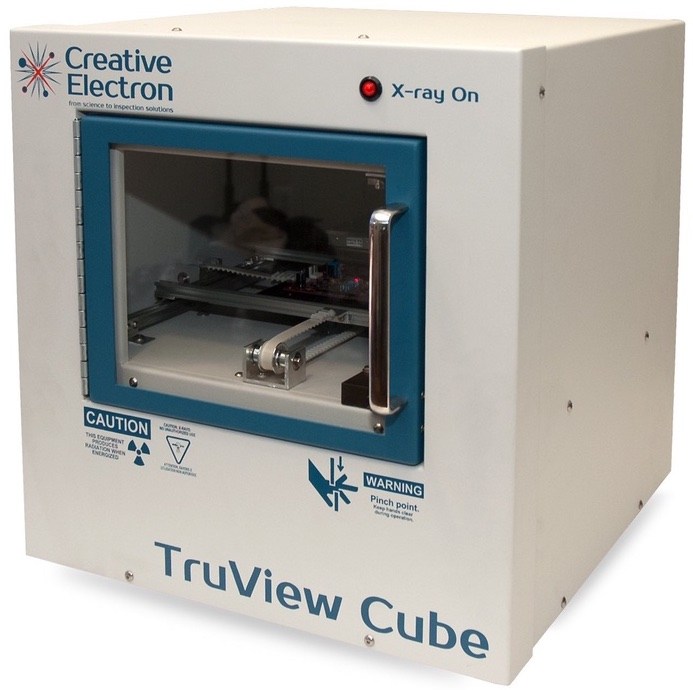

TruView™ Cube X-ray Inspection System is a fully motorized radiography system developed to meet the stringent requirements of electronics assembly and component inspection. Ideal for applications where sample size is limited to 6″x6″ (15x15 cm), the TruView™ Cube X-ray sits comfortably on your laboratory bench.

TruView™ Cube is easy to use and install, making it the most versatile and portable system on the market today. The TruView™ Cube has an amazing set of features that produce incredible X-ray images. The custom manipulation control allow you to move the sample inside the cabinet and to vary the power of the X-ray source.

TruView™ Cube can be configured in 2 different models:

- TruView Cube A - load and unload samples using front door. Motorized or automated motion system

- TruView Cube S – source on the top of the system and a large flat panel detector on the bottm, allowing your samples to lay right on top of the sensor. Ideal for NDT application and parts counting

Technical specifications

- X-ray Source Voltage: variable, up to 80kV.

- X-ray Camera: 4″/2″ high resolution image intensifier.

- Sample Manipulation: Motorized and controlled by keyboard.

- System Dimensions (LxWxH): 16“x16“x28“ (40x40x75 cm).

- Maximum Visible Sample Area: 6”x6” (15x15 cm).

- Included Software: TruView 10 Standard.

- Included Computer: PC with latest Windows OS, fully networkable.

- Optional Upgrades: TruView 10 Premium, cart, sample rotation mechanism, joystick, laboratory bench.

- Safety: FDA compliant and CE certified. Cabinet fully shielded with multiple interlocks, keyed start switch, and emergency stop switch. Certified to operate worldwide.

TruView™ Prime offers outstanding image quality in a benchtop configuration. For several years technical teams had to make a decision: to buy a large X-ray inspection system for good image quality, or to buy a benchtop X-ray system for low image quality. The TruView™ Prime breaks this paradigm. The TruView™ Prime can be configured as a generic X-ray inspection system, ideal for use in PCB inspection (BGA and QFN), or it can be configured in a high magnification mode (using a transmissive X-ray source), ideal for semiconductor failure analysis.

TruView™ Prime was designed to be easy to use. Utilizing the principles of “plug-and-play”, the TruView™ Prime can be installed and ran with minimal training. The TruView™ Prime is a semi-automated X-ray inspection system when powered by the TruView™ 10 Premium software.

TruView™ Prime can be configured in 3 different models:

- TruView Prime A – load and unload samples using front door. Motorized or automated motion system

- TruView Prime R – automated inspection of components in tape and reel. A must have for component inspection and counterfeit detection

- TruView Prime S – source on the top of the system and a large flat panel detector on the bottm, allowing your samples to lay right on top of the sensor. Ideal for NDT application and parts counting

Technical specifications

- X-ray Source Voltage: variable, up to 80kV, 90kV, 110kV, or 130kV.

- X-ray Camera: 3″x4″, or 4″x6″ 14-bit flat panel.

- Sample Manipulation: Motorized and controlled by keyboard. Automation available with TruView 10 Premium.

- System Dimensions (LxWxH): 31”x31”x35” (80x80x90 cm) (without cart or reel-to-reel).

- Maximum Visible Sample Area: 12″x12″ (30x30 cm).

- Included Software: TruView 10 Standard.

- Included Computer: PC with latest Windows OS, fully networkable.

- Optional Upgrades: TruView 10 Premium, cart, sample rotation mechanism, stage tilt, joystick, laboratory bench. Inspection automation and custom path macros.

- Safety: FDA compliant and CE certified. Cabinet fully shielded with multiple interlocks, keyed start switch, and emergency stop switch. Certified to operate worldwide.

TruView™ Fusion X-ray Inspection System is the most versatile X-ray machine in the market today. Capable of inspecting samples up to 20″x20″ (50x50 cm) or 20″x48″ (50x122 cm) in X mode, the TruView™ Fusion can be powered with X-ray sources from 80kV to 150kV.

TruView™ Fusion offers unique feature - the fully automated defect detection capability. The TruView™ 10 Software Premium allows you to program a complete suite of tests in the TruView™ Fusion, which can be repeated on a batch of samples. With full pass/fail capabilities, this system can either assist or replace an experienced operator.

TruView™ Fusion built as a powerful platform, can be configured in 6 different models:

- truview Fusion A – load/unload samples using front door

- truview Fusion B – load/unload samples using integrated conveyor belt on a single side of the system

- truview Fusion C – samples travel through using integrated conveyor belt on both sides of the system

- truview Fusion R – automated inspection of components in Tape & Reel for counterfeit detection

- truview Fusion S – Source on the top and large flat panel detector on the bottom allows to place the samples right on top of the sensor – ideal for NDT

- truview Fusion X – side boxes expand the total inspectable area to 20”x48” (50x122 cm)

Technical specifications

- X-ray Source Voltage: variable, up to 80kV, 90kV, 110kV, 130kV or 150kV.

- Spot Size: Microfocus.

- System Resolution: Depends on sample.

- X-ray Camera: 3”x4” (7,5x10 cm), 5”x6” (13x15 cm) ) 14-bit flat panel in A, B, C, R, X models or 12”x10” (30x25 cm), 17”x17” (43x43 cm) in S model 16-bit flat panel.

- Sample Manipulation: Fully automated X, Y, Z, and X-ray sensor tilt. Sample and stage rotations also available.

- System Dimensions (LxWxH): 48”x36”x65” (122x92x165 cm).

- Maximum Visible Sample Area: 20″x20″ (50x50 cm) in A, B, C, D, R, S modelsx or 20″x48″ (50x122 cm) in X models.

- Included Software: TruView 10 Standard.

- Included Computer: PC with latest Windows OS, fully networkable.

- Optional Upgrades: TruView 10 Premium, cart, sample rotation mechanism, stage tilt, joystick, laboratory bench. Inspection automation and custom path macros.

- Safety: FDA compliant and CE certified. Cabinet fully shielded with multiple interlocks, keyed start switch, and emergency stop switch. Certified to operate worldwide.

TruView™ Fusion CT is an incredible 3D X-ray system that allows to take full computed tomography images of samples in a few minutes. Built with patent pending algorithms and state of the art hardware capable of absolute measurements inside samples, the TruView™ Fusion CT is the 3D X-ray system that should meet all customer’s requirements.

TruView™ Fusion CT software comes equipped with a special plugin that outputs .stl files – the standard format for 3D printing. That means you can 3D X-ray scan a sample with your TruView™ Fusion CT and – in a matter of minutes – have the CT volume printed. How is this better than an optical 3D scanner? The CT of the sample allows you to “see inside the sample”, which means you can print a cross section of the sample instead of only the outer shell. You can even correct defects of your original sample in the CT volume so that the 3D printout is corrected/modified.

Technical specifications

- X-ray Source Voltage: 80kV, 90kV, 130kV, or 150kV.

- Spot Size: Microfocus.

- System Resolution: Depends on sample.

- X-ray Sensor: 3”x4” (7,5x10 cm), 5”x6” (13x15 cm), 9”x6” (23 x 15 cm) 14-bit flat panel.

- Sample Manipulation: Magnification + turn table.

- System Dimensions (LxWxH): 48”x36”x65” (122x92x165 cm).

- Turntable Option 1: Ø150mm rotary plate with multiple tapped holes and 4 mounting brackets for objects up to 7lb (3 kg).

- Turntable Option 2: Ø300mm rotary plate with multiple tapped holes for objects up to 165lb (75 kg).

- Included Software: TruView CT Software.

- Included Computer: 2xPC (acquisition + reconstruction) with Windows OS, fully networkable.

- Safety: FDA compliant and CE certified. Cabinet fully shielded with multiple interlocks, keyed start switch, and emergency stop switch. Certified to operate worldwide.