TruView Parts Counter AI is an innovative optical counter of electronic components or small mechanical parts packed in embossed tapes. The principles of operation is X-ray scanning of a package and counting components using image processing methods. Algorithms are powered by original Artificial Intelligence (AI) engine.

TruView Parts Counter AI has following advantages against traditional counters:

- Possibility of scanning components also packed in protective packages for example in ESD shielding bags;

- Three steps counting operation – put the package in the drawer, press start button, take out - taking always 8 seconds for the whole reel (independently of the components’ number on it);

- Automated identification of shapes of counted components without requirement of component pre-selection or any other forms of counter adaptations for example by scanning labels or defining setups;

- Self-adaptation to new shapes of components and self-increasing of accuracy thanks to artificial intelligence algorithms;

- Very simple operation that doesn’t require specially educated and trained staff;

- No periodic or annual maintenance required;

- Flexibility – only software or data base upgrade is required to extend functionalities with the new components’ shapes or with a new packages new;

- Full protection against X-ray radiation with lead shield;

- Status logging of performed operations in log files;

- Possible integration with MES (Manufacturing Execution Systems) and ERP (Enterprise Resource Planning).

Thanks above TruView Parts Counter AI allows:

- To extremely quickly count components every time before and after the assembly progress to avoid technology lines stops caused by deficit of components on pick & place feeders or to avoid stock unconformities;

- To avoid accidental damages of components and packages that happens while mechanical counting.

- To reduce human factor in making stock inventory process as a source of potential mistakes;

- To improve stock management, reduce losses caused by incorrect deliveries and by losses on way stock-assembly-stock;

- To speed-up running, periodical and annual stock taking;

- To reduce employment at monotonous, „non-humanitarian” counting operations.

TruView Parts Counter AI for sure from technical point of view has solved the problem of the extremely quick components counting. But from economical point of view, because of applied X-ray technology is an expensive equipment that can be accepted by the big EMSs and OEMs. It seems that it’s luxury for you - don’t be so sure. Please estimate and compare possible costs and profits per year. The biggest players are already counting using XRH Count – and you?

Technical specifications

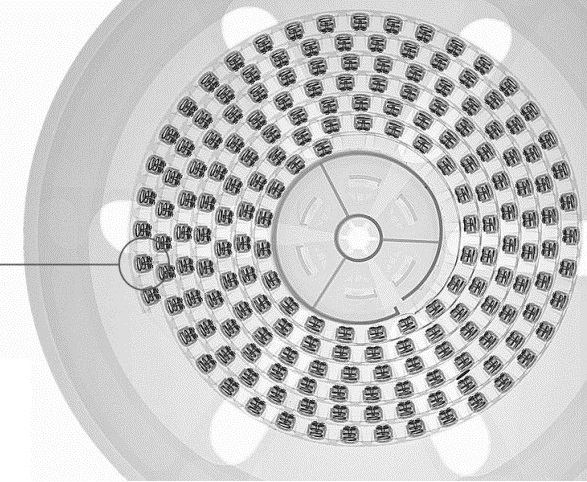

- Reel Count: Four 7″ reels or single 17″ reel at a time

- Reel Manipulation: Drawer to load/unload reels

- Max. Reel Size: 17″

- Min. Part Size: 01005

- Accuracy: Better than 99%

- X-ray Source: 80kV

- X-Ray sensor: 16-bit

- System Dimensions (LxWxH): 24”x24”x44” (60x60x112 cm)

- Power supply: 100/220V

- User Interface: Touchscreen

- Peripherials: Bar Code Scanner, Printer

- Industry 4.0: Full CFX integration.

- ERP/MRP/MES Integration: Major ERP systems, including Oracle, SAP, Epicor, ….; PanaCIM MES system

- Included Software: AI TruView Parts Counter.

- Included Computer: PC with Windows OS, fully networkable.

- Warranty: 3-year warranty.

- Safety: FDA compliant and CE certified. Cabinet fully shielded with multiple interlocks, keyed start switch, and emergency stop switch. Certified to operate worldwide.